Nantong

Rainbow Heavy Machinery Co., Ltd. (hereinafter referred to as “RHM”) &Koch

Solutions acquisition signing ceremony and “GENMA” environmentally friendly

bulk material equipment introductory conference ended successfully at Nantong

on July 9, 2019. Grain Robot, Catenary Bucket Chain Ship Un-loader, Scraper

Ship Un-loader, Bucket Chain Ship Un-loader, Cement Pneumatic Ship Un-loader,

Grain Un-loader and mobile harbor crane, a total of 7 GENMA products made a

grand debut on that ceremony.

Huang

weifeng, secretary of Gangzha district, Jürgen Barke, State Secretary in the

Ministry of Economic Affairs of Saarland, Germany, Wu Jian, Chairman of Rainbow

Machinery Co., Ltd. attended the conference and delivered a speech. Agents,

suppliers, customer representatives, financial institutions media, etc., more

than 300 guests from all over the world witnessed the event. The newly released

GENMA products focused more on efficiency and environmental protection. GENMA

team employed innovative techniques to create innovative designs and redefine

the concept of the high efficiency of port machines.

Looking

back at the development of the port machinery industry in the year of 2018,

efficient intellectualization, energy-saving and environmental protection are

the trends for future development. Ports and terminals in the country and

abroad are accelerating the proses of upgrading intelligent operation, and the

market growth potential is huge. At present, the port machinery industry is in

need of equipment products with the characteristics of high efficiency,

intelligence and environmental protection.

Therefore,

in 2019, GENMA brought in a newly upgraded and highly efficient, intelligent

environmental protection series products. This series of new products were

independently developed and designed by Rainbow Heavy Machinery Co., Ltd., and

has many advantages such as “highly efficient, intelligent, energy-saving,

environmentally friendly”.

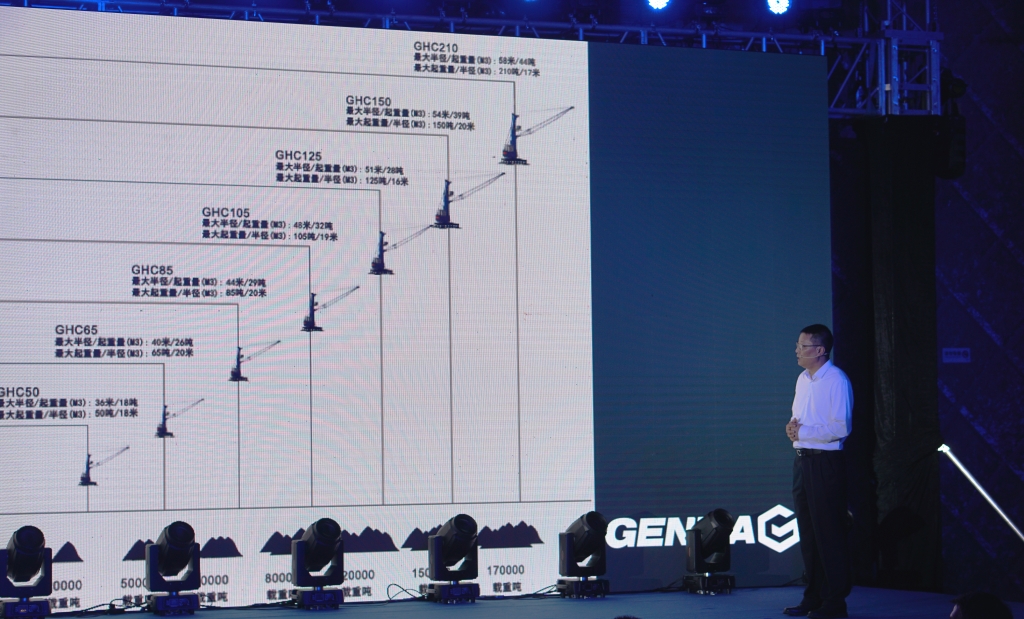

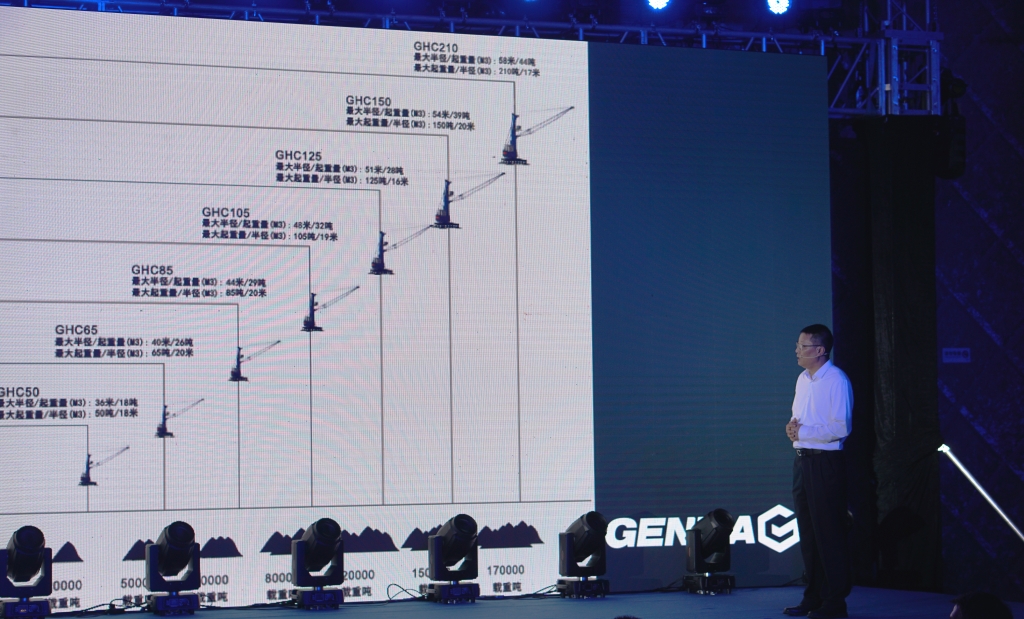

Highly-efficient

"Efficiency"

is the eternal pursuit of GENMA. Among the newly released products, GENMA's

third-generation mobile harbor crane has an operating efficiency improvement of

nearly 20% compared to the previous two generations of mobile harbor cranes.

The third-generation GENMA mobile harbor crane not only enables the grab to be

able to adapt to a variety of materials, but also optimizes each grab action, and

can capture the material to the maximum extent within different working ranges,

and to realize the functions of the design in order to grab more material per

unit time. Yes, grab becomes more efficient!

The

newly released “GENMA” Scraper Ship Un-loader also showed impressive strength

in saving energy and boosting efficiency. After two years of repeated testing,

the unloader is now combined with the optimization of EDEM Bulk-sim simulation

software. If compared with traditional grabs, the current unloading efficiency

of the product has increased by at least 25%, and the unit energy consumption

is reduced by nearly 30%.

Intelligentization

Intelligentization

is the forward direction of national strategic development. "Made in China

2025" also leads the development of product technology in the direction of

intelligence (intelligent technology, intelligent equipment).

Intelligentization not only reduces the difficulty of the operational process,

but also creates greater value for customers. This is the innovation force of

GENMA products.

The

upgraded GENMA mobile harbor crane is equipped with a smart loading and

unloading system and reliable anti-shake technology to quickly calculate,

select loading and unloading paths and execute work plans in a short time. All

these seemingly intelligent and complex operations only require the operator to

set the starting point and the target point of the job. The system

automatically calculates the path of the job. With the updated and anti-shake

technology, the container operation is smoother and more stable, which means

that it saves more time in the boxing process, greatly improves efficiency and

reduces the operator’s workload.

Energy-saving

The

innovation of GENMA products lies in lightweight and energy-saving. Compared to

other ship unloaders, the GENMA Scraper Ship Un-loader has an unloading

efficiency of 1,500 tons per hour and a unit energy consumption of less than

0.4 kWh/t, which poses an excellent cost-saving advantage.

During

the conference, GENMA also launched a grain unloader called G-bot,and a

“positive and negative pressure integrated conveyor” for unloading soybeans,

corn, wheat and other types of grain; large tonnage negative pressure pneumatic

unloading machine for powdery materials such as cement and mineral powder. The

peak unloading efficiency of the GENMA large-tonnage negative pressure

pneumatic ship unloader reaches 400 t/h, and the power consumption is 1kwh/t.

The new structure of the pneumatic unloader is simpler and more compact,

lighter-weight, simpler in operation, less in clearance volume, and higher in

production efficiency. The pneumatic unloader uses a high-power and high-speed

permanent magnet motor to drive the fan to improve transmission efficiency

while reducing energy consumption.

Energy

consumption of the GENMA chain bucket unloader is low, and the specific energy

consumption coefficient is 0.2~0.25Kwh/t. The clearance volume is extremely

low, and can be controlled below 2.5%. The hopper of the overhanging section

can be closely attached to the hopper to grab material, and it is not necessary

to arrange a cleaning machine such as a pusher for this kind of unloader.

Environmentally

Friendly

Regarding

the environmental performance of Gemma's third-generation mobile harbor crane

products, we shall start explaining from 2 points of view:

On

one hand, basic environmental performance: we provide customers with the option

of shore power. Users can easily switch between diesel engines and shore power.

On

the other hand, hydraulic accumulators can store and reuse energy. This is a

new feature of the third generation GENMA mobile harbor crane. It is worth

mentioning that we chose to employ the leading energy storage technology in the

market, which is very stable and reliable in nature.

For

GENMA scraper ship unloader, pneumatic unloader and other equipment, the

material conveying process is in a sealed state, so it is free of material

spills and possesses good environmental performance, hence solves the common

dust pollution problem of traditional equipment, and truly achieve

environmental protection.

In

addition to the characteristics of high unloading efficiency and energy saving,

GENMA catenary ship unloader, GENMA Gantry chain unloader and the GENMA bucket

chain unloader also pose other highlights. The research and development team of

Rainbow Heavy Machinery has conducted in-depth research and made many R&D

innovations.

GENMA

catenary unloader uses an endless rope winch system for ship movement. This

feature ensures compact structure, optimizes drive arrangement, shorten the

length and cost of the port; the chain structure is optimized to facilitate the

replacement of the hopper; the belt conveyor is optimized in order to combine

inclined belt conveyor and the horizontal belt conveyor.

GENMA

Bucket Chain Ship Un-loader adopts a floating reclaiming head to solve the surging

problem and ensure stable work process. The unique counterweight balance system

reduces the center of gravity and weight of the machine; The driver's cab is

independently supported and is made to ensure comfortable operation experience

and good vision while in operation.

Wu

Jian, Chairman of Rainbow Co., Ltd. said at the new product launch conference,

“As an industry-leading company, Rainbow Heavy Machinery Co., Ltd. has always

been committed to creating value for customers. Providing highly efficient and

environmentally friendly and state-of-the-art products for customers under the

premise of cost optimization, in order to accelerate the development of

intelligent and environmentally friendly bulk handling equipment

worldwide."

RHI WeChat

RHI WeChat